When it comes to the efficient operation of mini excavators, the final drive plays a crucial role. This essential component is responsible for transmitting power from the engine to the tracks, allowing the excavator to move and operate smoothly. In this blog post, we’ll explore the key components and functions of the final drive, providing a comprehensive understanding of its importance in mini excavators.

What is the Final Drive?

The final drive, sometimes referred to as the travel motor, is a complex mechanical system located at the end of the drive train in mini excavators. It consists of several components that work together to convert the hydraulic power from the engine into mechanical power, which propels the tracks and enables movement.

Key Components of the Final Drive

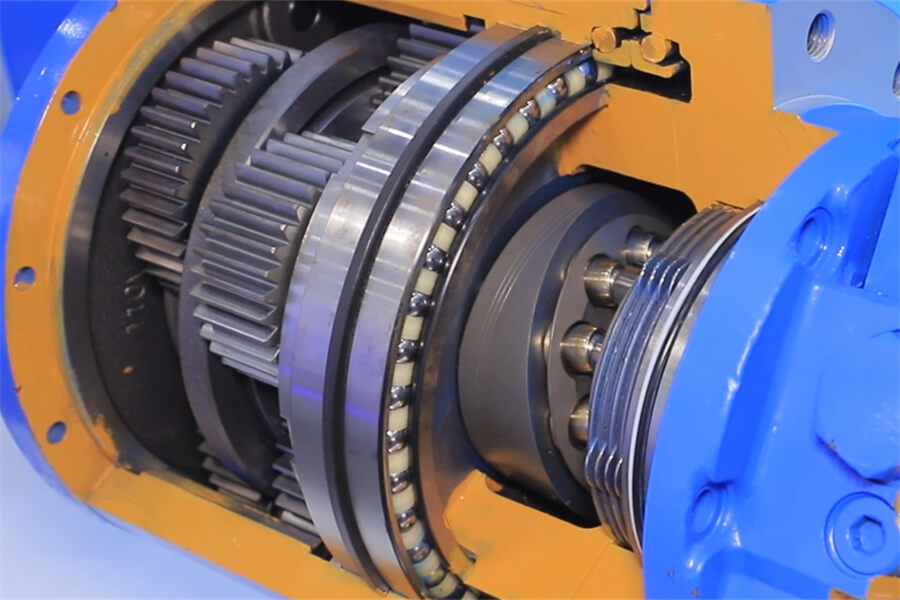

1.Hydraulic Motor: The hydraulic motor is the heart of the final drive. It receives hydraulic fluid from the excavator’s hydraulic pump and converts this fluid power into mechanical power. The efficiency and performance of the hydraulic motor directly impact the overall performance of the final drive.

2.Planetary Gear System: This gear system is essential for reducing the high speed generated by the hydraulic motor to a lower, more manageable speed. The planetary gear system consists of a sun gear, planet gears, and a ring gear. This arrangement allows for smooth and efficient power transmission, ensuring that the tracks receive the appropriate amount of torque.

3.Sprocket: The sprocket is a toothed wheel that engages with the tracks. It is directly connected to the output shaft of the final drive and is responsible for transmitting the rotational motion to the tracks. The design and condition of the sprocket significantly affect the excavator’s traction and stability.

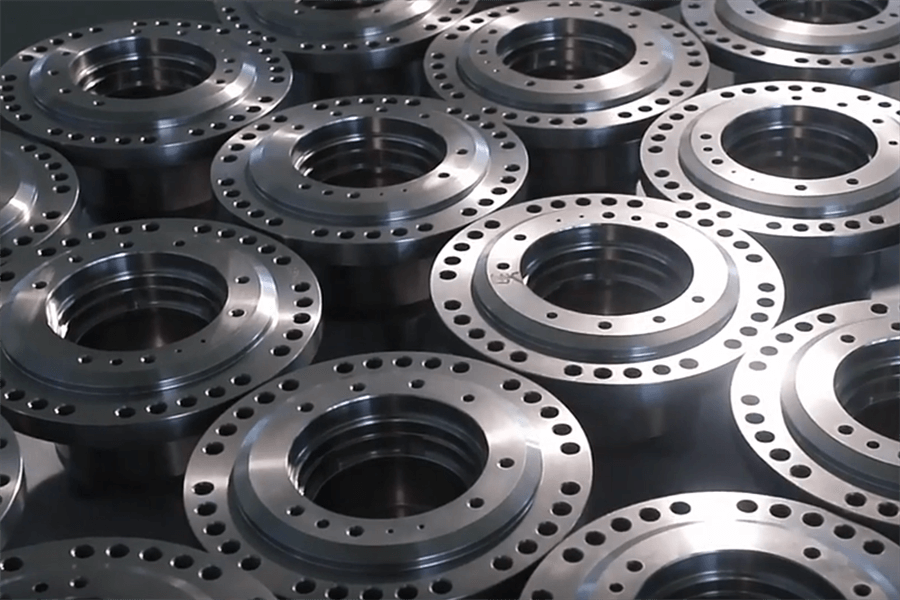

4.Housing and Seals: The final drive housing encases all the internal components, protecting them from external elements such as dirt, debris, and moisture. Seals are critical for preventing hydraulic fluid leaks, which can lead to reduced efficiency and potential damage to the internal components.

Functions of the Final Drive

1.Power Transmission: The primary function of the final drive is to transmit power from the engine to the tracks. This involves converting hydraulic energy into mechanical energy, which is then used to propel the excavator forward or backward. The efficiency of this power transmission determines the excavator’s overall performance.

2.Speed Reduction: The planetary gear system within the final drive reduces the high rotational speed of the hydraulic motor to a lower speed suitable for the tracks. This speed reduction is crucial for maintaining control and stability during operation.

3.Torque Multiplication: In addition to reducing speed, the planetary gear system also increases the torque delivered to the tracks. This torque multiplication ensures that the excavator can handle heavy loads and challenging terrains with ease.

4.Directional Control: The final drive enables precise directional control of the excavator. By varying the hydraulic fluid flow to the hydraulic motor, the operator can control the speed and direction of the tracks, allowing for smooth and accurate maneuvering.

Maintenance and Troubleshooting

Proper maintenance of the final drive is essential for ensuring the longevity and reliability of a mini excavator. Regular inspection and servicing of the hydraulic motor, planetary gears, sprocket, and seals can help prevent potential issues and costly repairs. Some common maintenance tasks include:

1.Checking hydraulic fluid levels and quality.

2.Inspecting and replacing worn-out seals.

3.Monitoring the condition of the sprocket and tracks.

4.Lubricating the planetary gear system.

In case of any abnormalities, such as unusual noises, vibrations, or reduced performance, it is important to troubleshoot and address the issue promptly. Consulting the manufacturer’s guidelines and seeking professional assistance can help diagnose and resolve final drive problems effectively.

Conclusion

The final drive is a vital component in mini excavators, playing a key role in power transmission, speed reduction, torque multiplication, and directional control. Understanding its components and functions can help operators and maintenance personnel ensure the efficient and reliable operation of these versatile machines. Regular maintenance and timely troubleshooting are essential for maximizing the lifespan and performance of the final drive, ultimately contributing to the overall productivity of the mini excavator.

Post time: Jul-30-2024