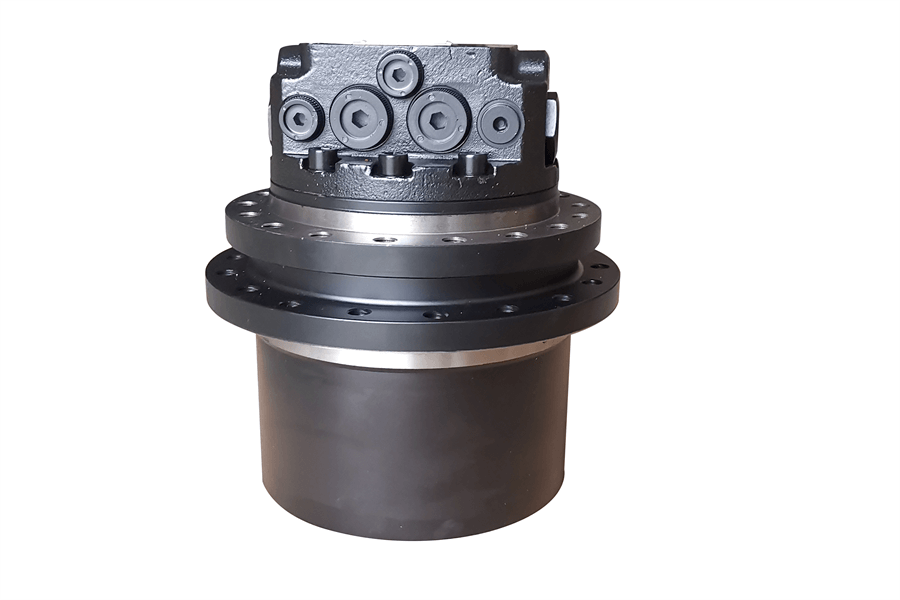

Mini excavators are indispensable machines on many construction sites, offering flexibility and efficiency for a variety of tasks. One of the most critical components of these machines is the final drive. This key element ensures the smooth transmission of power from the engine to the tracks, enabling the mini excavator to move and operate effectively. Regular maintenance of the final drive is crucial to ensure optimal performance and longevity of the machine. Here’s why maintaining the final drive is so important.

1.Prevention of Costly Breakdowns

A well-maintained final drive reduces the risk of unexpected breakdowns, which can halt construction work and lead to costly downtime. Regular inspection and maintenance allow you to identify and address potential issues before they escalate into major problems. This proactive approach helps in avoiding expensive repairs and replacements.

2.Enhanced Performance and Efficiency

The final drive plays a significant role in the overall performance of a mini excavator. A properly maintained final drive ensures efficient power transmission, which translates to better machine performance. This efficiency is crucial for completing tasks quickly and effectively, saving both time and fuel costs.

3.Extended Lifespan of the Mini Excavator

Routine maintenance of the final drive contributes to the extended lifespan of the mini excavator. By keeping the components in good working condition, you minimize wear and tear, ensuring that the machine remains operational for a longer period. This longevity is particularly important for maximizing the return on investment for construction companies.

4.Safety Considerations

Safety is a paramount concern on any construction site. A malfunctioning final drive can lead to operational hazards, posing risks to the operator and other workers. Regular maintenance helps in identifying and rectifying issues that could compromise the safety of the machine, thereby creating a safer working environment.

5.Preservation of Warranty

Many mini excavators come with warranties that require regular maintenance as a condition for coverage. Failing to adhere to these maintenance schedules can void the warranty, leaving you unprotected against potential defects or issues. By keeping up with regular maintenance, you ensure that the warranty remains valid, providing an added layer of protection for your investment.

Key Maintenance Practices

To keep the final drive in optimal condition, consider the following maintenance practices:

1.Regular Inspections: Conduct thorough inspections of the final drive at regular intervals to identify signs of wear, leaks, or damage.

2.Lubrication: Ensure that the final drive is adequately lubricated with the appropriate oil to reduce friction and prevent overheating.

3.Cleaning: Keep the final drive clean and free from debris that could cause damage or interfere with its operation.

4.Timely Repairs: Address any identified issues promptly to prevent them from worsening and causing more significant problems.

In conclusion, regular maintenance of the final drive is essential for ensuring the reliability, efficiency, and safety of mini excavators. By prioritizing maintenance, you not only extend the lifespan of the machine but also protect your investment and enhance overall productivity on the construction site. Make maintenance a routine practice and enjoy the benefits of a well-performing mini excavator.

Post time: Aug-06-2024