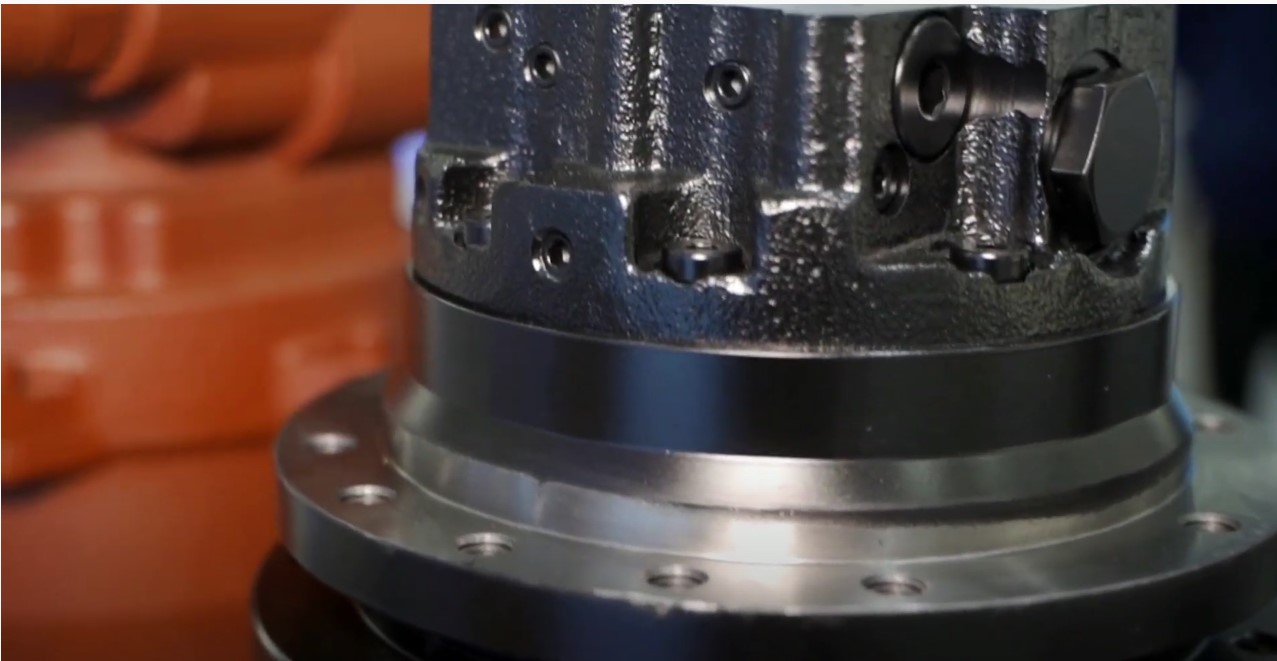

HOW TO EXTEND THE LIFE OF HYDRAULIC MOTORS

A hydraulic motor is a complex travel device with a limited lifespan that requires proper maintenance. Preventive measurements can help to smoothen the operation process and significantly prolong its life. Motor inspection frequency should be based on the specific motor type, operating conditions and manufacturer recommendations. In general, most of the motors and motor parts should be checked at least every 6 months. Here is 4 essential things you should pay attention to.

Motor ventilation

If your machine works in unventilated or poorly ventilated areas, your hydraulic motor can easily get overheated, which often causes various problems. Dust and dirt are the biggest enemies of the motor ventilation system, and to prevent this issue you have to blow away the dirt frequently. If you want your motor to serve you for a long time, make sure its temperature stays as cool as possible.

Loose connections

Something else you must check regularly is all the electrical connections of your motor. Loose connections can cause many problems with different parts of a motor, including joint failure caused by cold or creep flow during load cycles.

Voltage imbalance

Voltage imbalance happens when the voltage of three phases is different from each other. Overheating, different vibrations and torque pulsations are the results of voltage imbalance, which affects motor lifespan.

Bearings

Recently to boost sales many bearing manufacturers claim their bearings to be ‘greased-for-life’. Don’t get tricked by that! Bearings play a very important role in motor operation and need to be maintained properly. When trying to calculate bearing lifespan it is important to consider materials and lubrication frequency. Incorrect maintenance can shorten bearing life sufficiently.

We hope our tips were useful for you! If you are interested in purchasing high quality hydraulic motors, please leave a message, and our sales team will contact you right away!

WEITAI Marketing Department

Post time: Jan-17-2023