Variable displacement piston pumps are crucial components in hydraulic systems, offering flexibility and efficiency in fluid power applications. Among the various designs available, axial and radial configurations stand out for their distinct characteristics and suitability in different operational scenarios. Understanding the differences between axial and radial designs is essential for selecting the optimal pump for specific industrial or mobile hydraulic applications. In this article, we delve into the intricacies of axial and radial variable displacement piston pumps, comparing their design principles, advantages, disadvantages, and typical applications.

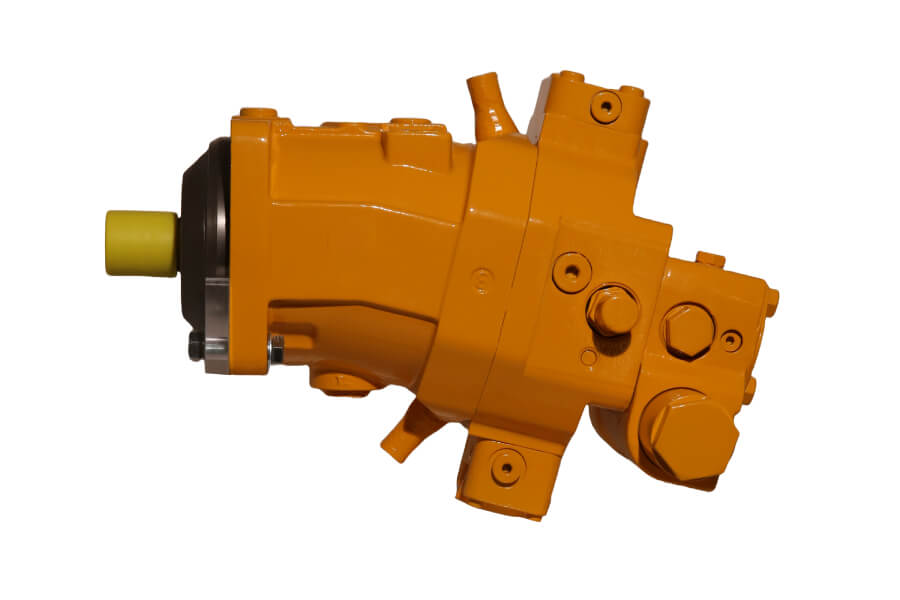

Axial Variable Displacement Piston Pumps

Axial piston pumps derive their name from the arrangement of pistons around a central axis within the pump housing. This design typically involves pistons arranged parallel to the pump shaft, which rotates to generate hydraulic pressure. Here are some key features and considerations regarding axial piston hydraulic pumps:

- Design and Operation:

- Axial piston pumps operate by reciprocating pistons within cylinder bores. These pistons are typically housed in a rotating swash plate or cam mechanism.

- The reciprocating motion of pistons is converted into rotary motion, driving the fluid flow through inlet and outlet ports.

- Adjustment of the swash plate angle or cam position varies the piston stroke length, thereby regulating the pump’s displacement and output flow.

- Advantages:

- High Efficiency: Axial piston pumps are known for their high operational efficiency, particularly at higher pressures and speeds.

- Compact Size: The axial design allows for a relatively compact pump size compared to other types, making it suitable for applications with space constraints.

- Versatility: These pumps can handle a wide range of pressures and flow rates, offering flexibility in various industrial and mobile hydraulic systems.

- Disadvantages:

- Complexity: The design complexity, especially concerning the swash plate or cam mechanism, can lead to higher manufacturing costs and maintenance requirements.

- Noise and Vibration: Axial piston pumps may produce more noise and vibration compared to radial designs, which can be a consideration in noise-sensitive applications.

- Applications:

- Axial piston pumps find extensive use in applications requiring precise control of hydraulic systems, such as industrial machinery (e.g., presses, injection molding machines) and mobile equipment (e.g., construction machinery, agricultural vehicles).

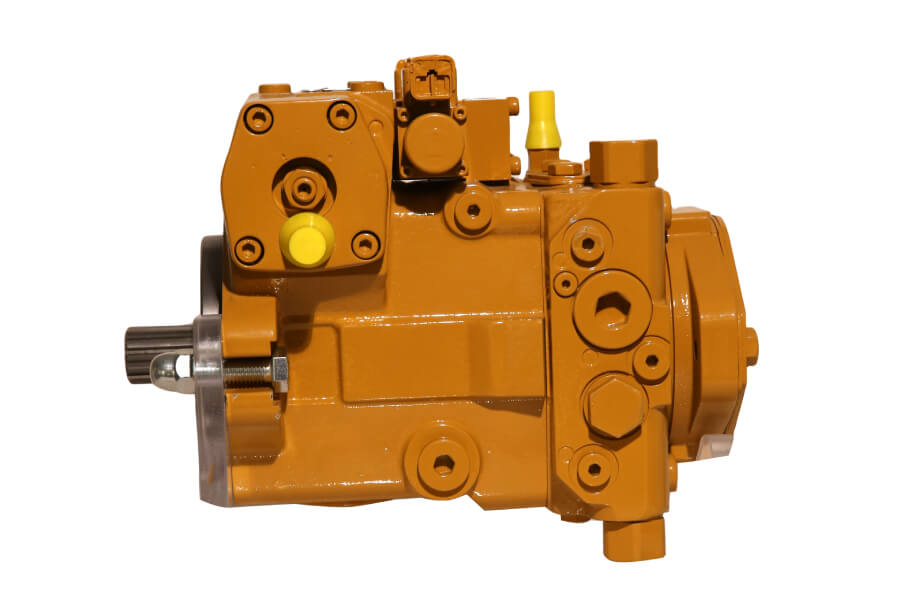

Radial Variable Displacement Piston Pumps

In contrast to axial designs, radial piston pumps feature pistons arranged radially around a central drive shaft. This configuration offers distinct advantages and considerations:

- Design and Operation:

- Radial piston pumps utilize pistons that move radially inward and outward within cylinder bores.

- The rotation of the central shaft causes the pistons to reciprocate, creating a pumping action that draws in and expels fluid through ports.

- Adjustment of the piston stroke, often through a tilting swash plate or eccentric cam mechanism, regulates the pump’s displacement and flow output.

- Advantages:

- High Pressure Capability: Radial piston pumps are well-suited for high-pressure applications, offering robust performance under demanding conditions.

- Smooth Operation: Due to the radial arrangement of pistons, these pumps can operate with reduced noise and vibration levels compared to axial designs.

- Durability: The robust construction of radial piston pumps lends itself to longevity and reliability, making them suitable for continuous-duty applications.

- Disadvantages:

- Bulkier Size: Radial piston pumps typically have a larger footprint compared to axial designs, which can limit their use in applications where space is constrained.

- Lower Efficiency at Lower Speeds: Efficiency may decrease at lower operational speeds compared to axial designs, impacting performance in some applications.

- Applications:

- Radial piston pumps are commonly employed in heavy-duty hydraulic systems where high pressures and reliability are paramount. Examples include hydraulic presses, industrial power units, and certain types of marine and aerospace applications.

Choosing Between Axial and Radial Designs

When deciding between axial and radial variable displacement piston pumps, several factors should be considered:

- Application Requirements: Assess the specific hydraulic system requirements, including pressure levels, flow rates, and space constraints.

- Operational Efficiency: Consider the desired efficiency and performance characteristics across the pump’s operational range.

- Noise and Vibration Levels: Evaluate the impact of noise and vibration on the surrounding environment or machinery operation.

- Maintenance and Lifecycle Costs: Factor in the long-term maintenance requirements and associated costs of each pump design.

In conclusion, both axial and radial variable displacement piston pumps offer unique advantages and are suited to different types of hydraulic applications. Axial pumps excel in compactness, efficiency at higher speeds, and versatility, while radial pumps shine in high-pressure environments, durability, and smoother operation. Selecting the right pump design involves matching these attributes with the specific demands of the application, ensuring optimal performance and longevity in hydraulic systems.

Understanding the nuances between axial and radial designs empowers engineers and system designers to make informed decisions that align with operational goals and efficiency requirements. Whether for industrial machinery, mobile equipment, or specialized hydraulic systems, the choice between axial and radial variable displacement piston pumps plays a critical role in achieving reliable and efficient fluid power performance.

Post time: Jun-25-2024