When it comes to final drive motors, choosing between hydraulic and electric types can significantly impact the performance, efficiency, and operational costs of your machinery. Both types have distinct advantages and disadvantages, making them suitable for different applications. In this article, we’ll compare hydraulic and electric final drive motors in detail to help you make an informed decision.

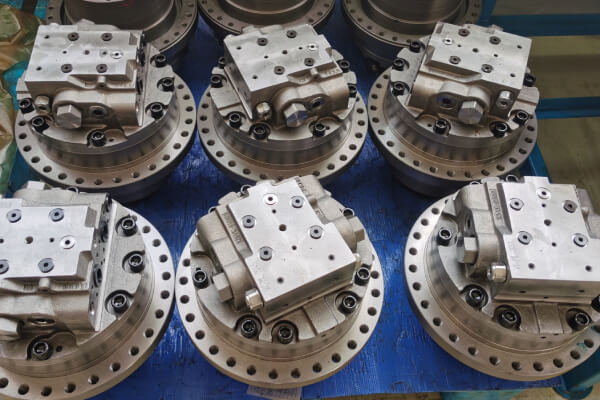

Hydraulic Final Drive Motors

Advantages

1. High Power Density

Hydraulic motors are renowned for their ability to deliver a high amount of power relative to their size and weight. This makes them ideal for heavy-duty applications where space is at a premium, such as in construction equipment and industrial machinery.

2. Durability and Reliability:

These motors are built to withstand harsh operating conditions, including extreme temperatures, dirt, and moisture. Their robust construction makes them highly reliable for demanding environments.

3. Smooth Operation:

Hydraulic motors provide smooth and consistent torque, which is crucial for applications requiring precise control. This characteristic is particularly beneficial in applications like excavators and loaders, where smooth, controlled movements are essential.

4.Scalability:

Hydraulic systems can be easily scaled up or down, making them versatile for a range of applications from small machinery to large industrial equipment. They can handle variable loads effectively, making them adaptable to different operational demands.

Disadvantages

1. Complexity and Maintenance

Hydraulic systems are complex, with numerous components such as pumps, valves, and fluid reservoirs that require regular maintenance. This complexity can lead to higher operational costs and downtime if not properly managed.

2. Energy Inefficiency

Hydraulic motors are generally less energy-efficient compared to electric motors. Energy losses occur in the form of heat generated by the hydraulic fluid, which can reduce overall system efficiency.

3. Environmental Concerns:

Hydraulic systems pose environmental risks due to potential leaks and the need for proper disposal of hydraulic fluid. Spills can lead to soil and water contamination, necessitating stringent environmental controls.

Electric Final Drive Motors

Advantages

1. Energy Efficiency

Electric motors are typically more energy-efficient than hydraulic motors. They convert electrical energy to mechanical energy with minimal losses, leading to lower operational costs and reduced environmental impact.

2. Low Maintenance

Electric motors require less maintenance compared to hydraulic motors. There are no fluids to replace, and the components tend to have longer lifespans, resulting in reduced downtime and lower maintenance costs.

3. Precision and Control

Electric motors offer superior precision and control, making them ideal for applications that require exact movements and positioning. This is particularly beneficial in robotics, automated machinery, and precision manufacturing.

4. Environmentally Friendly

Electric motors produce no emissions and have fewer environmental concerns related to leaks or disposal. They contribute to cleaner operations and can be integrated into green technology initiatives.

Disadvantages

1. Power Density Limitations

While electric motors are improving, they generally offer lower power density compared to hydraulic motors. This can be a limitation in applications requiring very high power in a compact space, such as in heavy construction equipment.

2. Initial Cost

The upfront cost of electric motors can be higher than hydraulic systems, especially when considering the need for advanced control systems and power electronics. However, this initial investment can be offset by lower operating and maintenance costs over time.

3. Temperature Sensitivity

Electric motors can be sensitive to extreme temperatures, which may affect their performance and reliability in harsh conditions. Proper thermal management systems are essential to ensure consistent operation.

Applications and Suitability

Hydraulic Motors

Best suited for heavy-duty applications requiring high power and durability, such as construction machinery (excavators, bulldozers), industrial equipment, and off-road vehicles. Their ability to handle high loads and harsh environments makes them ideal for these uses.

Electric Motors

Ideal for applications needing precision, efficiency, and lower maintenance, such as robotics, automated machinery, electric vehicles, and some types of agricultural equipment. They are particularly well-suited for environments where energy efficiency and environmental impact are critical considerations.

Conclusion

The choice between hydraulic and electric final drive motors depends largely on your specific application requirements. Hydraulic motors are preferred for their high power and durability in demanding environments, making them suitable for heavy-duty machinery. On the other hand, electric motors are favored for their energy efficiency, precision, and lower maintenance needs, making them ideal for applications requiring exact control and environmentally friendly operations. By understanding the strengths and limitations of each type, you can select the best motor for your machinery to achieve optimal performance and efficiency.

Post time: Jun-14-2024