Mini excavators are indispensable in many construction and landscaping projects due to their versatility and efficiency. The final drive, a critical component of these machines, converts hydraulic energy into mechanical energy, driving the tracks. However, like any mechanical part, the final drive is subject to wear and tear. Recognizing the signs of wear and addressing them promptly can prevent costly repairs and downtime. Here are some common signs of final drive wear and tear in mini excavators and how to address them.

1. Unusual Noises

Signs:

- Grinding, clicking, or whining sounds coming from the final drive area.

Causes:

- Worn-out bearings.

- Damaged gears or components inside the final drive.

Solutions:

- Inspect the final drive thoroughly.

- Replace damaged bearings or gears.

- Regularly check for metal shavings in the hydraulic fluid, which indicate internal damage.

2. Leaking Hydraulic Fluid

Signs:

- Puddles of hydraulic fluid under the excavator.

- Decreased hydraulic fluid levels.

Causes:

- Worn or damaged seals.

- Cracks in the final drive casing.

Solutions:

- Replace the seals to prevent further leakage.

- Inspect the casing for cracks and repair or replace if necessary.

- Regularly check and maintain the hydraulic fluid levels.

3. Reduced Performance

Signs:

- Sluggish movement of the tracks.

- Difficulty in steering or controlling the excavator.

Causes:

- Internal wear in the final drive.

- Hydraulic issues affecting the final drive’s performance.

Solutions:

- Conduct a hydraulic pressure test to ensure the system is operating correctly.

- If internal wear is identified, consider rebuilding or replacing the final drive unit.

- Ensure regular maintenance of the hydraulic system.

4. Overheating

Signs:

- Final drive becoming excessively hot during operation.

- Warning lights or indicators on the excavator’s control panel.

Causes:

- Low hydraulic fluid levels.

- Excessive friction due to worn components.

Solutions:

- Check and top up hydraulic fluid levels as needed.

- Replace worn-out components to reduce friction and heat buildup.

- Ensure proper ventilation and cooling mechanisms are functioning correctly.

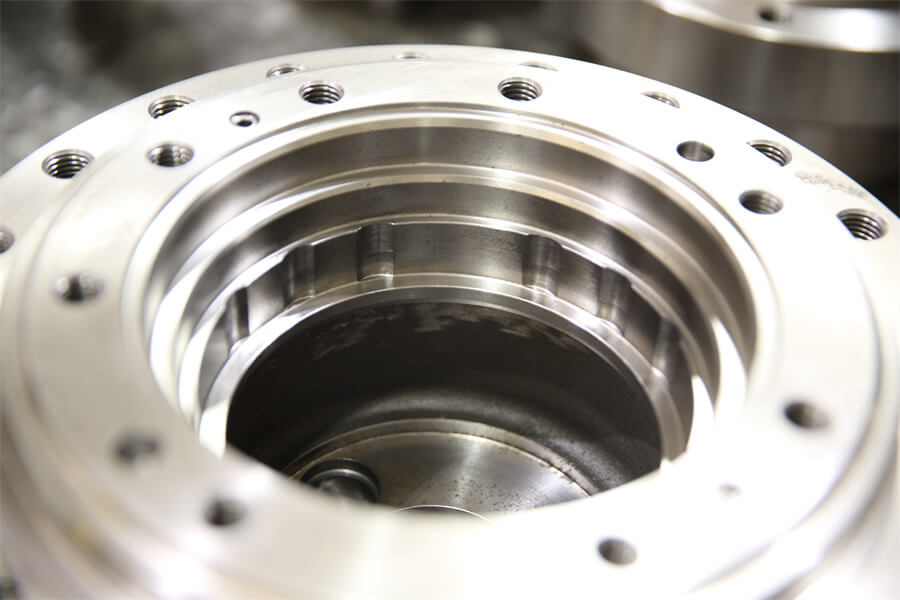

5. Visible Wear and Damage

Signs:

- Cracks, dents, or other visible damage on the final drive casing.

- Worn sprockets or track components.

Causes:

- Physical impact or collisions.

- Prolonged use without maintenance.

Solutions:

- Conduct regular visual inspections of the final drive and track components.

- Repair or replace damaged parts immediately to prevent further issues.

- Implement a routine maintenance schedule to catch wear early.

Preventative Maintenance Tips

- Regular Inspections: Conduct routine inspections to catch signs of wear early. Look for leaks, unusual noises, and visible damage.

- Hydraulic Fluid Maintenance: Regularly check and maintain hydraulic fluid levels. Replace fluid and filters according to the manufacturer’s recommendations.

- Proper Operation: Ensure operators are trained to use the mini excavator correctly to avoid unnecessary strain on the final drive.

- Scheduled Servicing: Follow the manufacturer’s servicing schedule to keep the final drive and other components in optimal condition.

- Immediate Repairs: Address any signs of wear and tear immediately to prevent further damage and costly repairs.

Conclusion

The final drive is a vital component of mini excavators, and its proper maintenance is crucial for the machine’s performance and longevity. By recognizing the signs of wear and tear early and taking appropriate action, you can ensure your mini excavator remains reliable and efficient, minimizing downtime and maximizing productivity. Regular maintenance and timely repairs are the keys to keeping your equipment in top shape.

Post time: Aug-02-2024