When it comes to operating an excavator efficiently and effectively, one of the most critical components to consider is the track motor. Excavator track motors play a pivotal role in the machine’s mobility and productivity on various terrains and in different conditions. Whether you’re purchasing a new excavator or replacing an existing track motor, selecting the right one can significantly impact your project’s success. Here’s a comprehensive guide to help you navigate this crucial decision.

Understanding Excavator Track Motors

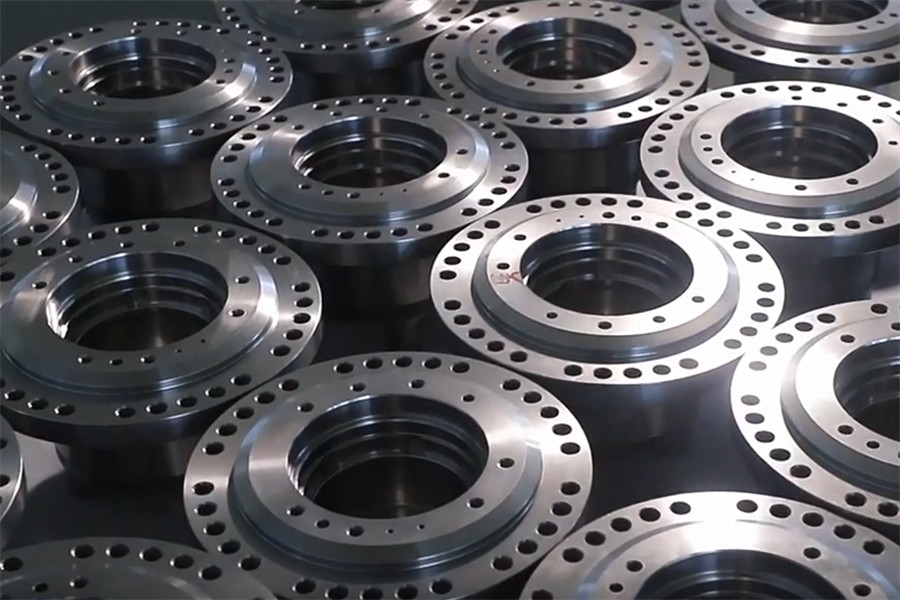

Excavator track motors are responsible for converting hydraulic power into mechanical power to drive the machine’s tracks. They come in different types and configurations, but their primary function remains consistent: providing the necessary torque and speed for maneuverability and operation on construction sites.

Factors to Consider

1.Machine Specifications: Start by understanding your excavator’s specifications, including its weight, size, and intended applications. The track motor you choose must be compatible with these factors to ensure optimal performance and longevity.

2.Type of Track Motor: Excavator track motors typically fall into two categories: hydraulic and electric. Hydraulic motors are common for their robustness and ability to handle heavy-duty tasks, while electric motors are known for their efficiency and quieter operation. Consider which type aligns best with your operational needs and environmental considerations.

3.Performance Requirements: Evaluate the performance requirements of your projects. Factors such as maximum torque output, speed range, and efficiency under varying loads should influence your decision. For intensive excavation jobs, a track motor with high torque capabilities may be preferable, whereas speed and precision might be prioritized for tasks requiring frequent repositioning.

4.Terrain and Conditions: The nature of the terrain and environmental conditions in which you operate will impact the durability and effectiveness of the track motor. Factors such as slopes, soft soils, mud, and debris should be taken into account when selecting a motor that can withstand these challenges without compromising performance.

5.Maintenance and Serviceability: Consider the ease of maintenance and availability of service for the track motor you choose. Opt for models that offer straightforward maintenance procedures, accessible parts, and reliable support from manufacturers or suppliers.

Making an Informed Decision

When choosing the right excavator track motor, it’s essential to weigh all these factors carefully. Consulting with equipment specialists or manufacturers can provide valuable insights tailored to your specific needs and operational requirements. Additionally, reviewing customer reviews and testimonials can offer practical perspectives on real-world performance and reliability.

Conclusion

Selecting the right excavator track motor involves a thoughtful evaluation of your machine’s specifications, operational demands, and environmental considerations. By understanding these factors and leveraging expert guidance, you can ensure that your excavator operates at its peak performance, enhancing productivity and efficiency on construction sites.

Choosing a track motor isn’t just about functionality; it’s about investing in the long-term success of your projects. By prioritizing compatibility, performance, and durability, you can make a confident decision that aligns with your operational goals and ensures optimal performance from your excavator.

Post time: Jul-19-2024